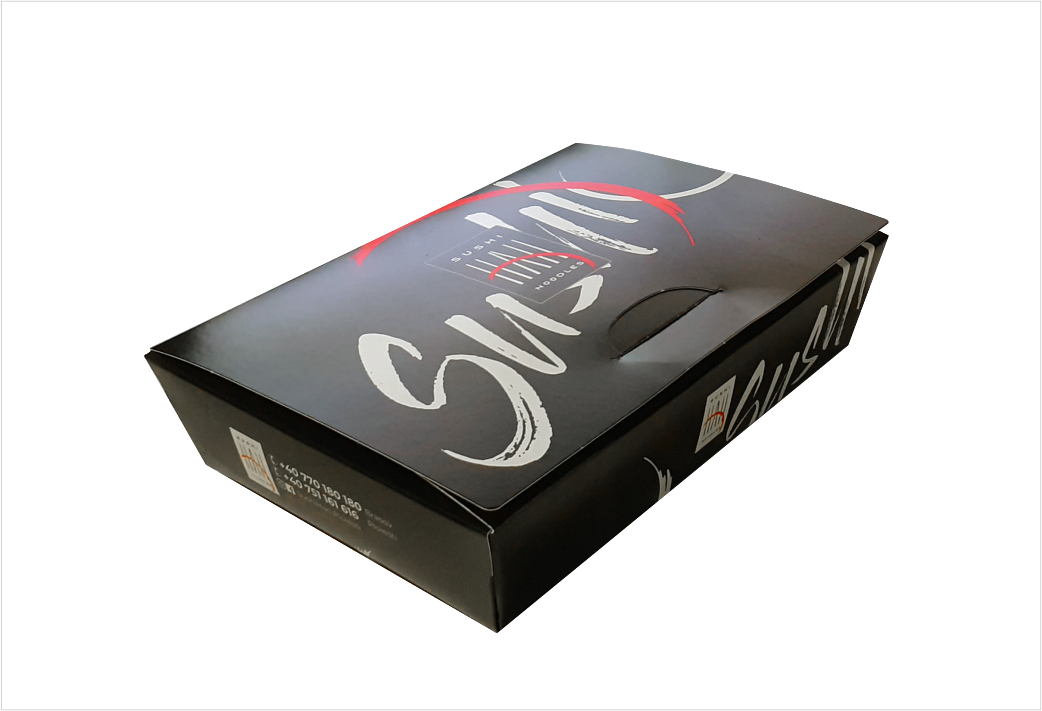

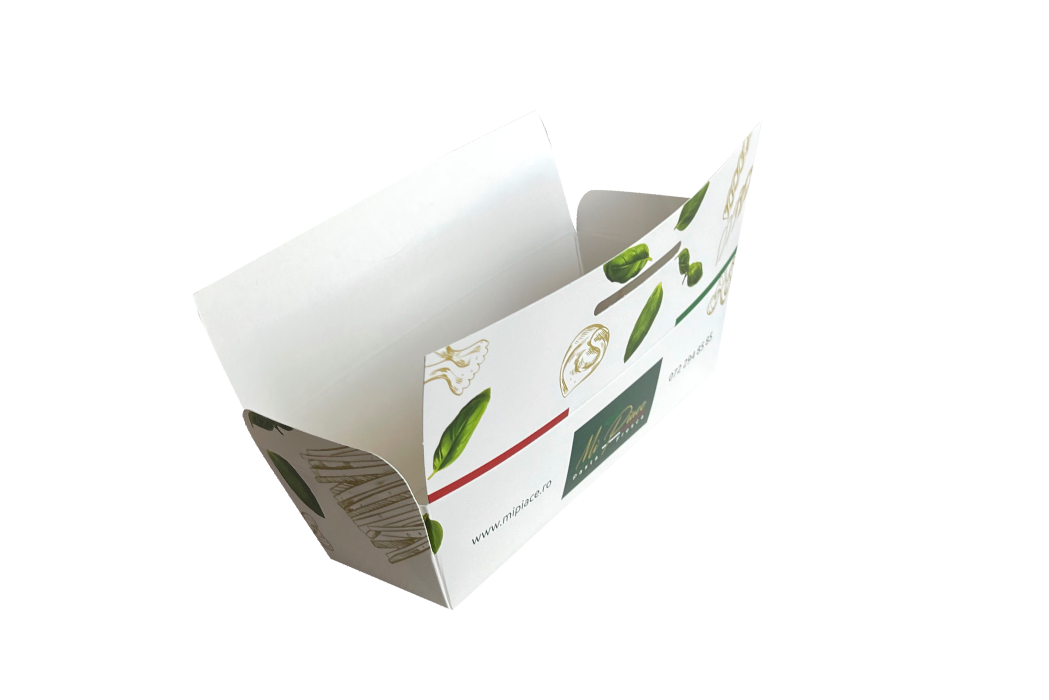

These paper cotainers are the best way of serving to go or delivery and can be custom printed with the brand of your restaurant.

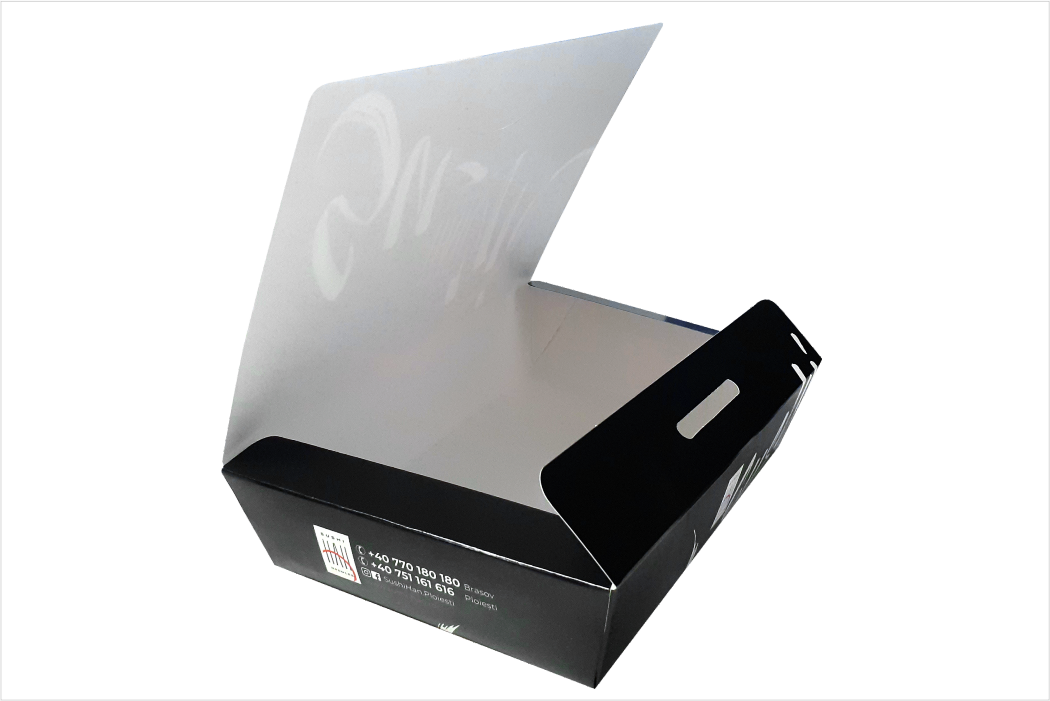

The box is made out of a single layer of cardboard of the highest quality, coated with a thin film of polyethylene, thus becoming resistant to grease, condensation and water. The raw materials we use are sustainable, EU-sourced and eco-friendly.

The printing technology we use renders the desired graphics at the highest resolution. The inks used in the personalization process are odorless and food-safe certified.

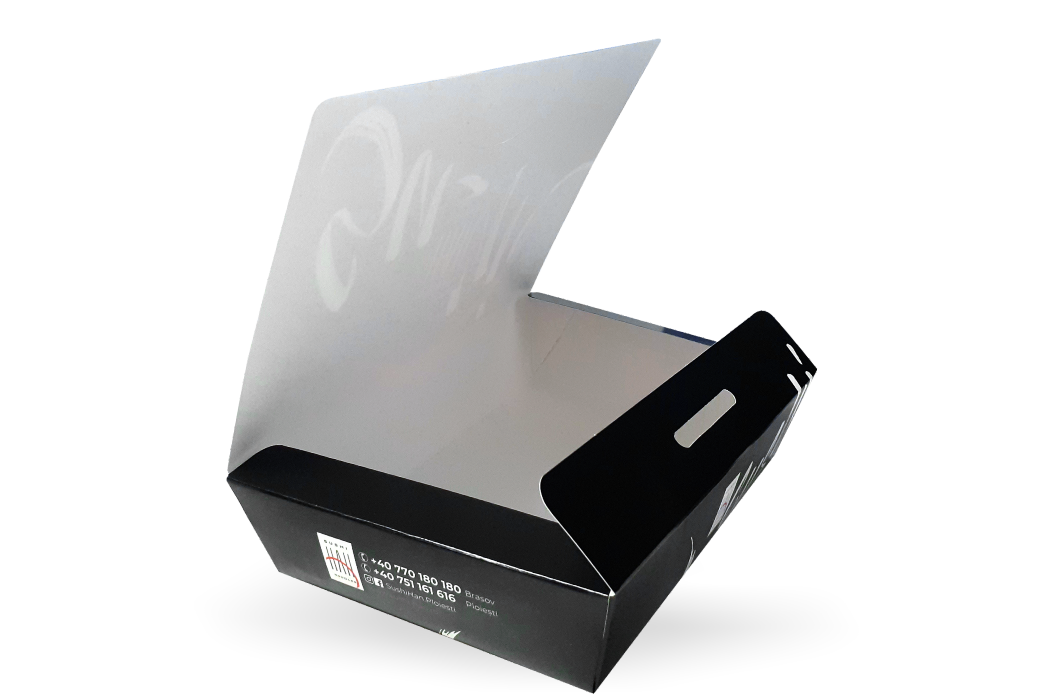

These boxes are available in several sizes and with different opening systems.

These boxes can be glued in 1, 2, 3, 4 and 6 points.